Collaboration with Axetris

CSEM’s latest collaboration with Axetris AG has led to the development of a state-of-the-art and user-centric quality control (QC) platform. It utilizes advanced Neural Network (NN) and Machine Learning (ML) technologies alongside CSEM’s VISARD program to detect, diagnose, and categorize faults on Micro-Electro-Mechanical (MEMs) or Micro-Optic (MO) dies. Capable of lifelong learning, the system is easily adaptable and can be trained to cope with changes in production processes or fault criteria.

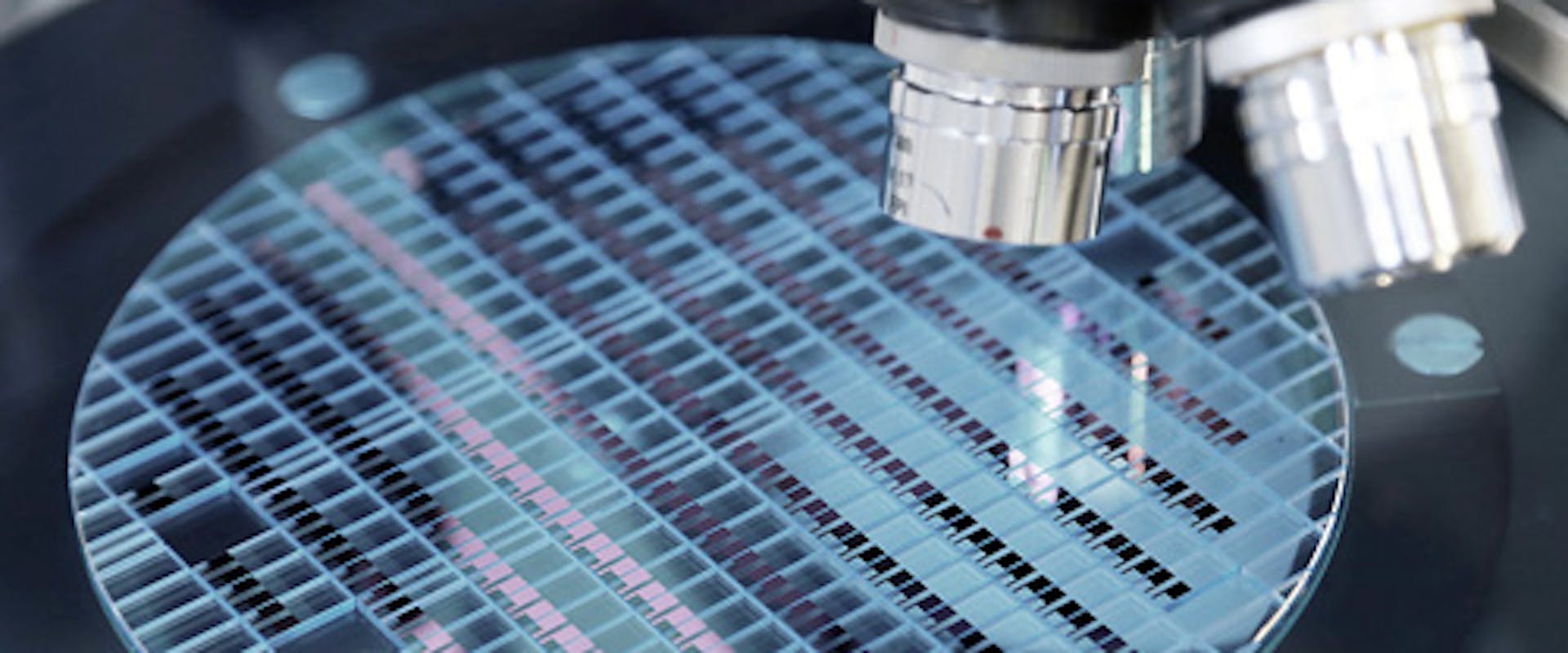

Today, MEMs dies are found in virtually every piece of electronic hardware. These tiny integrated devices play a significant role in ensuring the accuracy and performance of everyday systems; failure of these components could be catastrophic to human goods, making the detection and diagnosis of faults during their production of vital importance to any manufacturer.

Fabricated using integrated circuit batch techniques, MEMs dies undergo multiple checks during the manufacturing process to evaluate their quality. Initially, they pass through an advanced Automatic Visual Inspection (AVI) machine, which can detect defects on large wafers containing multiple MEMs dies.

“The formation of chipped edges, cracks or debris on the surface of these minuscule components is inevitable during the fabrication process,” explains Matthias Höchemer, Head of Robotics & ML at CSEM. “When these faults occur, AVI systems are useful as they locate surface anomalies, image the fault, categorize it and provide a map to mark which dies in the batch are affected.”

Utilizing the data provided by the AVI machine, quality engineers are then responsible for categorizing the faults and determining if they are critical or non-critical, that is, if the dies are suitable for use or not. This hands-on QC approach guarantees the dies' long service life but for the engineers it can be a tedious, labor and time-intensive process.

“Ensuring the quality of our products is our top priority,” says Andreas Mann, Process Engineer at Axetris, “and while our current quality control process is highly effective (utilizing an advanced AVI system and skilled inspectors) we saw an opportunity to optimize the whole procedure. In doing so, we wanted to help ease the stress load on our quality controllers and speed up inspection processes.”

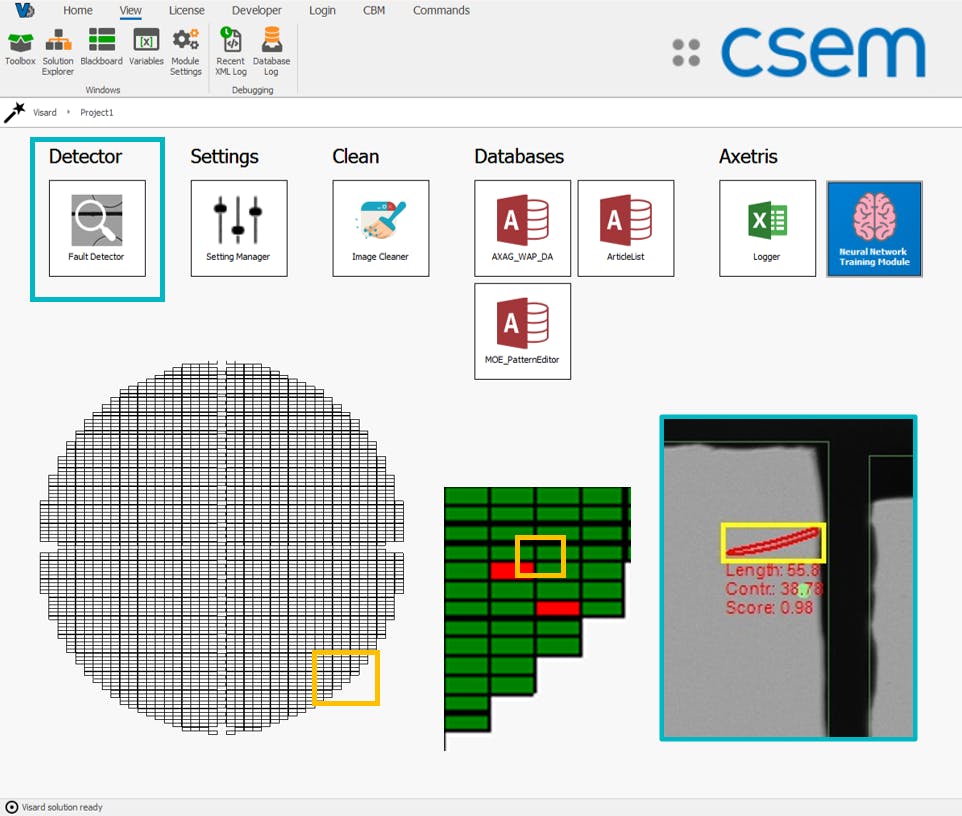

Hence, CSEM alongside Axetris has now developed an intelligent QC platform utilizing image data supplied by Axetris’ current AVI system. These images are run through CSEM designed NN and ML algorithms that are implemented using CSEM’s vertical process integration platform, VISARD. This software can diagnose, detect, label, and categorize faults on the wafer/individually affected dies (e.g. fault position, size, type). The information is then presented in a user-friendly manner within the VISARD platform, which automatically determines if the faults are critical or non-critical.

“The system removes the need for manual fault categorization and significantly speeds up inspection time, while at the same time improving its quality assurance,” adds Matthias Höchemer, “and what’s more, the strength of NNs lies in their ability to be dynamically trained. Should the engineers at Axetris want to change their inspection processes or adjust the algorithms’ decision criteria, they can load a separate and specially designed interface on the VISARD platform and independently fine-tune our algorithms. Changing a parameter only takes a minute and all settings are automatically versioned within the integrated versioning control system, which can track or even undo a changed setting. This makes sure any operational changes can be fully traced by the quality and process engineers.”

“The learning capabilities of this new QC platform mean we can quickly train the NN with a few examples of new faults in a new ‘environment’ and we are ready to go,” observes Andreas Mann, “we know the more we use the system the better the software will become as it continually learns. In addition, the detailed, quantitative feedback we obtain is a great help in systematically improving our processes.”

“We have partnered with CSEM on a variety of different projects over the years, but this is the first time we’ve entered into the realms of Artificial Intelligence and Deep Learning with them,” notes Simon Tschupp, Manager of Process Engineering at Axetris, “after a successful feasibility study, we are delighted with the advanced QC platform, and are now ready to test it over a sustained period in our production environment.”

Both companies are now looking deeper into the smart future to identify new process, quality, and yield optimization areas.