March 18, 2025

Organoids & Organ-on-Chips: From Research Tool to Biomedical Application

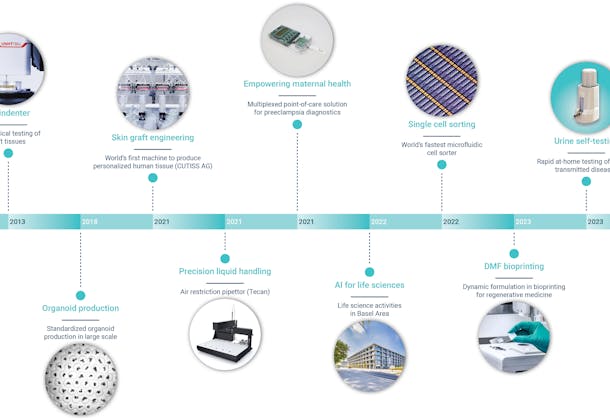

The 2-day workshop “Next-gen organ-on-chips & organoids” took place in mid-February at the Haus der Wirtschaft in Pratteln. At the invitation of CSEM, around 400 industry experts exchanged ideas on the latest developments in the field of organoids.

© CSEM - 400 experts participated to the 4th edition of the Next Gen Organ-on-Chips & Organoids Workshop