Hamilton’s liquid handling system unveils groundbreaking solution, powered by CSEM

- Automated liquid handling systems are essential for high-throughput screenings and assays in laboratory workflows.

- CSEM and Hamilton have developed an innovative system to perform routine accuracy testing of automated liquid handling systems.

- Microfluidic technology in combination with optimal image analysis ensure precise and accurate pipetting.

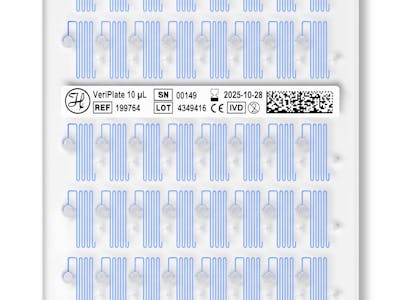

An innovative system to perform routine accuracy testing of automated liquid handling systems has been developed at CSEM in collaboration with lab automation market leader Hamilton. It is based on microfluidic technology in combination with optical image analysis. The microfluidic plate was invented at CSEM whereas the optical analysis and the robotic integration was developed by Hamilton who is now successfully commercializing the complete solution in the USA and EMEA under the name VeriPlate.

Thousands of labs in the pharmaceutical industry, diagnostics, and life sciences rely on automated liquid handling systems to perform high-throughput screenings and assays. When handling small volumes of only a few microliters precise and accurate pipetting is of the utmost importance—to comply with regulatory standards, to ensure reproducibility and avoid costly repetitions of experiments due to inconsistencies.

Quality control without much hassle

“An easy and fast quality control system can meet these needs and ensure confidence in the reliability of the pipetting workstation”, says Samantha Paoletti, Head R&BD, Life Science Technologies at CSEM. The idea for just such a system was conceived and patented at CSEM, and it has been further developed in collaboration with long-term CSEM partner Hamilton. The company, located in Bonaduz in the Swiss canton of Grisons, is the leading global manufacturer for automated liquid handling workstations. Hamilton has now launched the new quality control method under the name VeriPlate.

Samantha Paoletti underlines “We are delighted to have contributed to the launch of VeriPlate with Hamilton. Accurate monitoring of precise dispensing is crucial in laboratory workflows, and VeriPlate is set to transform this vital process. Our collaboration with Hamilton, a global leader in laboratory automation, underscores the impact of shared expertise. We are proud to support Hamilton as a key player from Graubünden, fostering growth and discovery in the life sciences.”

A simple microfluidic assay, a fast optical analysis

The workflow of the quality control test is simple and can be performed by lab personnel: At the heart of the system is an SBS plate containing 48 capillary slots. The automatic liquid handling system is programmed to pipette a small volume of colored verification liquid into the slots—anywhere between five and ten microliters. The dispensed liquid is then moving along the capillaries, whereby the covered distance depends on the sample volume.

Evaluation takes place with an optical scanner that determines the fluid level in the capillaries by image analysis. A report about the trueness and precision of the dispensed volumes is then automatically created in real-time. The quality control check therefore only takes a short while and the downtime of the pipetting robot is minimal.

Higher confidence in automated liquid handling systems

“This is a significant advancement in the safe use of automated liquid handling systems,” says Dr. Christoph Jung, Vice President Robotics, BU Robotics at Hamilton Bonaduz. “VeriPlate is an essential part of our Pipetting Excellence program and is expected to have a substantial impact on our business and the customer to implement a routine quality check in the laboratory workflow.”

The ability to routinely check the accuracy of the dispensed volumes will make life easier for scientists and lab personnel all over the world whose work relies on automated liquid handling systems.

The product launch of VeriPlate in April 2024 marks the successful completion of the collaboration between CSEM and Hamilton. The project illustrates how the highly qualified teams and state-of-the art facilities at CSEM can support industry partners—all the way from innovative ideas to commercialization.

Additional information

CSEM

Samantha Paoletti

Head R&BD, Life Science Technologies

T. +41 81 307 81 60

samantha.paoletti@csem.ch

Hamilton

Dr. Christoph Jung

Vice President Robotics, BU Robotics

T. +41 58 610 10 10

sales@hamiltoncompany.com

CSEM Media Relations

Sabina Müller

Media Relations

T. +41 79 361 50 12

media@csem.ch

About Hamilton

Hamilton is a leading global manufacturer, providing automated liquid handling workstations and laboratory automation technology to the scientific community. With a focus on innovative design, Hamilton products incorporate patented liquid handling technologies into a portfolio that includes liquid handling platforms, standard application-based solutions, small devices, consumables, and OEM liquid handling solutions. Known for advancing life science, clinical diagnostics, forensics and biotechnology industries, Hamilton products offer reliability, performance, and flexibility. Ensuring a continuous commitment to quality, Hamilton utilizes state-of-the-art manufacturing at production facilities in Reno, Nevada and Bonaduz, Switzerland and has earned a global ISO 9001 certification. Privately held, Hamilton maintains headquarters in Reno, Nevada; Franklin, Massachusetts; and Bonaduz, Switzerland, along with subsidiary offices throughout the world. www.hamiltoncompany.com

Visit the Hamilton Pipetting Excellence Program website to explore informative videos, and download an insightful Whitepaper.